1-800-322-9919Monday – Friday 8 AM – 4 PM (Pacific Time)

- Home

- Business

- Training

- Shop

- Shop By Category

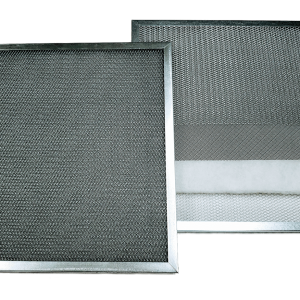

- Electrostatic Air Filters

- Accessories

- Replacement Parts

- Cobra Replacement Parts

- DuctMaster Replacement Parts

- TruckMaster Replacement PartsReplacement parts for the TruckMaster

- TurboJet Replacement Parts

- VentVac Replacement Parts

- Replacement Filters for Turbo JetsHere are the filters that are compatible with our entire line of Turbojet Air-Care equipment.

- Replacement Filters for VacuumsNeeding clean fresh filters for your Ductmaster or Vent Vac dryer duct cleaning equipment is of importance in the time of need while on a service call.

- Air Compressor Accessories

- Air Duct Cleaning Equipment

- Air Filters

- Air Purification

- Bio Carts

- Brochures

- Chemicals

- Cleaning Brushes

- Contact Cleaning

- Dryer Cleaning

- Equipment

- Foggers

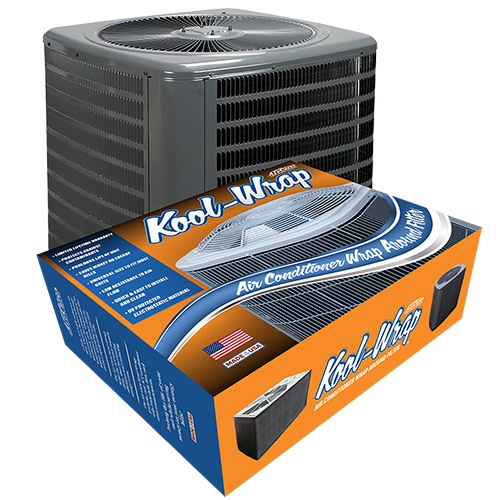

- Kool Wrap

- Negative Air Machines

- New Products

- Packages

- Safety Equipment

- Sales and Marketing

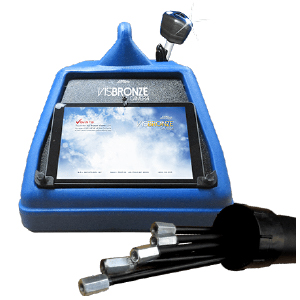

- Video Duct Inspection CamerasVideo Inspection Cameras that allow you to view and inspect the inside of air conditioner ducts to show customers and clients a easy and efficient way to see the years of buildup, dirt, and grime.

- New Products

- Bio Cart Containment Unit

- App Downloads

- Product Warranties

- Return-Refund Policy

- Legal Information

- Shop By Category

- About Us

- My Account

- Home

- Business

- Training

- Shop

- Shop By Category

- Electrostatic Air Filters

- Accessories

- Replacement Parts

- Cobra Replacement Parts

- DuctMaster Replacement Parts

- TruckMaster Replacement PartsReplacement parts for the TruckMaster

- TurboJet Replacement Parts

- VentVac Replacement Parts

- Replacement Filters for Turbo JetsHere are the filters that are compatible with our entire line of Turbojet Air-Care equipment.

- Replacement Filters for VacuumsNeeding clean fresh filters for your Ductmaster or Vent Vac dryer duct cleaning equipment is of importance in the time of need while on a service call.

- Air Compressor Accessories

- Air Duct Cleaning Equipment

- Air Filters

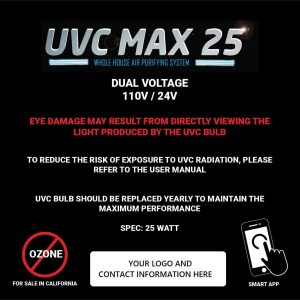

- Air Purification

- Bio Carts

- Brochures

- Chemicals

- Cleaning Brushes

- Contact Cleaning

- Dryer Cleaning

- Equipment

- Foggers

- Kool Wrap

- Negative Air Machines

- New Products

- Packages

- Safety Equipment

- Sales and Marketing

- Video Duct Inspection CamerasVideo Inspection Cameras that allow you to view and inspect the inside of air conditioner ducts to show customers and clients a easy and efficient way to see the years of buildup, dirt, and grime.

- New Products

- Bio Cart Containment Unit

- App Downloads

- Product Warranties

- Return-Refund Policy

- Legal Information

- Shop By Category

- About Us

- My Account