UNPACKING INSTRUCTIONS

Remove the outer box and inspect for damage. Report all damage immediately to your carrier. If special set-up instructions are required, they will be taped to the outside of the equipment or in the “Operating” section of this manual. Inspect all of the packing material for small parts before discarding packaging material. Report all damage to Air-Care immediately. Any attempt at repairing damages may void warranty.

PARTS CHECKLIST (See Parts and Accessories for expanded parts list)

TurboJet Max Main Assembly, with Wheels, Motor and Blower. Release the 4 side latches and lift the front of the upper section so it hinges up to check for filters. The HEPA filter will remain in the bottom section, the First Stage, 2” pleated filter will remain in the top section and the ½” electrostatic 2nd stage filter will be between them.

First stage, 18” x 24” x 2” Disposable Pleated Filter

Second stage, 18” x 24” x 1/2” Electrostatic Air Filter

Third stage, 18” x 24” x 6” Certified HEPA Filter

25’ Extension Power Cord.

The Rotation molded handle is shipped loose in the box.

SAFETY PRECAUTIONS

Always use safe and common sense precautions when working with Air-Care equipment. Do not block walkways with equipment, and remove delicate and breakable articles from the immediate work area. The following are precautions that should be reviewed by all persons who will be involved in the cleaning activity:

• Other than the 3 filters, there are no user serviceable components in Air-Care TurboJets. Only trained technicians should attempt to make internal repairs on this equipment.

• ALWAYS turn off the main power switch on the TurboJet front panel, or disconnect the power before opening or removing the doors or filters.

• Inspect AC power plug to be sure the ground pin is in place. DO NOT USE AN EXTENSION CORD. Plug directly into power outlet.

• NEVER connect power to Air-Care equipment unless all covers and safety shields are in place. Mechanical and electrical parts could activate and cause injury.

• NEVER allow anyone but a properly trained technician to use the equipment or cleaning products.

• All Air-Care equipment is designed for US standard 115 volt, 60 Hz AC. Most Air-Care equipment can be special ordered to meet other worldwide standards for a reasonable price and delivery schedule. Always check the specifications on the equipment before connecting electrical power to Air-Care equipment.

HANDLE INSTALLATION

Handle is bubble wrapped and packed near the bottom, front of TurboJet. It must be installed with the 4 bolts provided and your ½” socket wrench or nut driver.

SET-UP AND TESTING

Air-Care TurboJet Negative air machines are designed to “Pull” loose debris out of the air system to which they are connected and filter out harmful debris such as pollen, dust, mold spores and other debris with its 3 stage HEPA filter system. An agitating device to “Push” debris is required to properly clean an air system. The BrushMaster or Cobra Power Brush System or the Air Whisk and Sidewinder air tools are designed to loosen and agitate debris so the TurboJet can pull it out. See the “Duct Cleaning” section on page 4 of this manual for a summary of proper duct cleaning procedures.

To test the TurboJet, be sure all filters are in place and the Top is closed and latched in place.

1. Attach the 12 gauge x 25-foot power cord to a dedicated outlet (one that has no other devices currently connected).

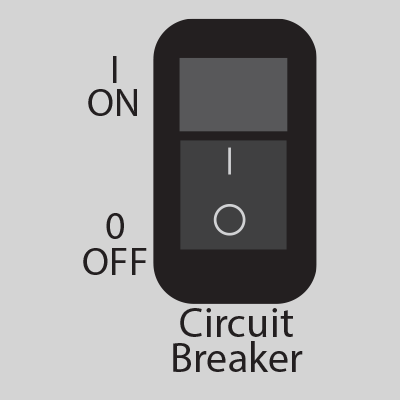

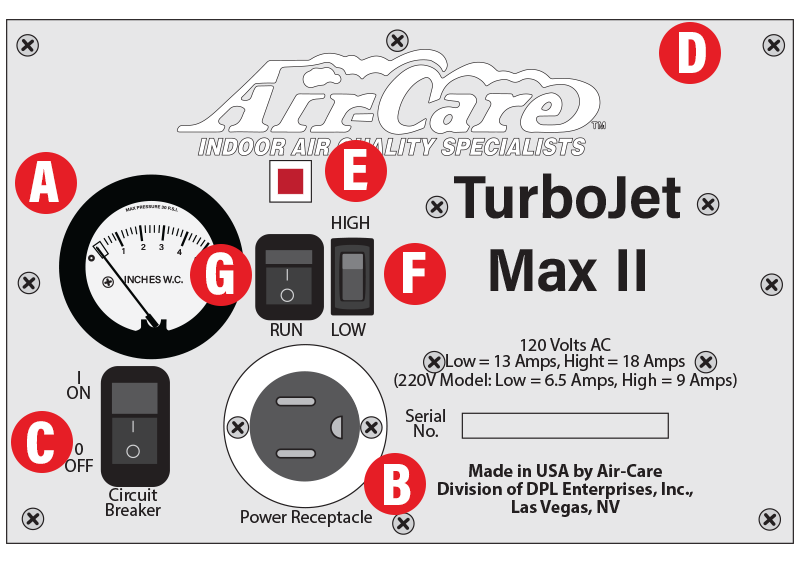

2. Turn on the circuit breaker/switch on the front panel.

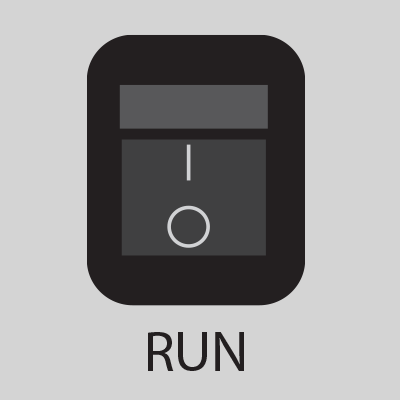

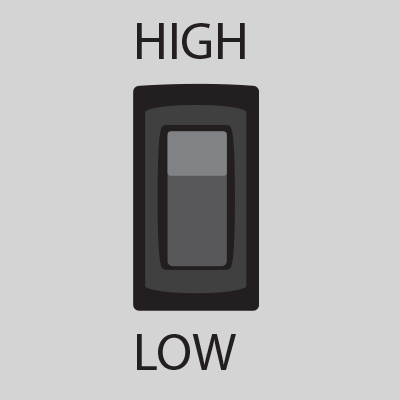

3. The Max 2 has “High” and “Low” speed, so Select either “Low” (13 Amp) or “Hi” (17 AMP) speed then turn on the “Start” switch.

4. The soft start feature will slowly climb to full speed within a few seconds and you should see the pressure gauge reading 1.8 to 4 inches of w.g. with nothing attached to the inlet.

5. If you observe other readings, see the trouble-shooting guide in this manual. The Single Speed TurboJet Max operates in the same manner.

DUCT CLEANING PROCEDURES

Effective duct cleaning can be accomplished with the TurboJet connected to one of the following positions in the duct system. The “best” location is determined by the specific configuration of the particular air system.

To obtain maximum “pull”, always keep the attaching hose as short and as straight as possible. If you have 25-foot hose, it is often useful to purchase an extra set of twist lock collars. Cut the hose into a 7 foot and an 18 foot length pieces to prevent “bunching up” when the TurboJet is near the connecting point of the air system.

A. With a basement or crawlspace air conditioner/furnace

Cutting an access hole in the side of the supply side main trunk line is very effective. Be sure that no airflows through the furnace. To stop air from coming through the furnace, block the duct openings with foam register plugs or cardboard and duct tape. An alternate way to block the airflow would be to slip the customers existing furnace filter in a plastic trash bag and reinstall. If there are returns in each room, you will also need to connect to the return trunk line at the furnace and block it off while cleaning the return ducts. Some Air-Care dealers use 2 TurboJets at the same time, one on the supply and one on the return.

B. Garage, interior closet or roof mounted up-flow air conditioner/furnace

just remove the diffuser grill from a large ceiling or wall mounted supply duct and use the Pogo Pole hose adapter to connect the TurboJet inlet hose to the system. Connecting to a large supply duct is very effective. Gravity will help “pull” dust and debris into the Turbojet.

In some cases, it may be best to attach the TurboJet to each Supply or return duct and insert the agitation device into that same duct opening to disturb debris as far up stream and down stream as possible.

To obtain maximum “pull”, always keep the attaching hose as short and as straight as possible.

1. Bring the TurboJet into close proximity to the planned connection ducts.

2. Connect 12 gauge electrical power cord directly to a suitable electrical outlet (110V, 15AMP or more)

3. Connect a 12” hose to the 12” TurboJet inlet.

4. Connect the other end to the most effective supply duct location using the optional Pogo Pole hose adapter or adapter plate.

5. Close off the return side of air handler by putting a filter in a plastic bag and reinstalling it into its holder.

6. Turn on the power switch located on the control panel.

7. Then turn on the start switch and the power light will go on and the blower motor will start providing strong suction. If a 20 amp Power outlet is used. The TurboJet Max will run on 15 amp or 20 amp circuits.

8. The TurboJet Max 2 can be set to “High” speed.

9. Follow recommended procedure to clean each supply, beginning at the most distant one, using the BrushMaster Power Brush System, Sidewinder or Air Whisk (sold separately).

After all ducts are cleaned, the ducts can be fogged with an EPA registered Deodorizer and Soot Set Sealer.

10. Before fogging the supplies, turn off the power switch.

11. Remove hose from the top of the TurboJet.

12. Place a piece of pellon, 20” X 22” over the 12” inlet.

13. Re-install the hose, and turn on the power switch.

14. Fog the supplies, beginning with the most distant supply.

15. When the fogging is complete, turn off the power; remove the hose from the TurboJet and the supply duct.

16. Remove and discard pellon.

17. Inspect first stage filter, if loaded with debris, Dump it out or replace as required.

18. Inspect electrostatic flex filter and wash if soiled.

19. Unplug power cords, put TurboJet back into the vehicle, and complete the job.

TROUBLESHOOTING GUIDE

SYMPTOM: Motor does not start when RUN switch turned on.

CHECK: Check connections to motor and control panel.

IF YES: Test motor and replace if bad.

IF YES: Check for manual reset button on motor.

IF YES: Check and reset circuit breaker and verify electrical outlet has power. If inverter has a slowly blinking green light call Air-Care. (The inverter is located behind the control panel inside the TurboJet Max 2 ONLY).

SYMPTOM: No vacuum with motor running.

CHECK: Is blower turning?

IF YES: Tighten shaft adapter bolts and align wheel & inlet cone. (Call Air-Care)

IF NO: Replace blower wheel and inlet cone.

SYMPTOM: W.G. 4.0” vacuum, with motor running

CHECK: Are the 1st stage pleated filter and 2nd stage Electrostatic filters clean?

IF YES: Replace HEPA filters as required.

IF NO: Clean 1st and 2nd stage air filters.

SYMPTOM: Insufficient “pull” at duct.

CHECK: Is the W.G. gauge meter reading 2.0” or more?

IF YES: Clean or replace filters as required.

IF NO: Check for disconnected, collapsed or broken system ducts.

IF NO: Inspect 12” hose for cracks or holes.

SYMPTOM: Circuit breaker trips when TurboJet is turned on.

CHECK: Is the TurboJet connected to a dedicated 115-volt, 15 or 20-amp line?

IF YES: Be sure TurboJet is connected directly to the power outlet. DO NOT use an extension cord.

IF YES: Be sure that only the original 12 gauge (or heavier) 25 ft. power cord is used on the TurboJet Max.

IF YES: Call Air-Care.

IF NO: Find an outlet on a line that does not have other devices connected to it.

DIAGNOSTIC LEDS

The drive contains two diagnostic LEDs to display the drive’s operational status.

Power On (PWR) – The “PWR” LED will illuminate green when the AC line is applied to the drive

Status LED (ST) – The “ST” LED is a triclor LED which provides indication for a fault or abnormal condition. The information provided can be used to diagnose an installation problem such as incorrect input voltage, overload condition, and drive output miswriring. It also provides a signal which informs the user that all drive and microcontroller operating parameters are normal. Table 1 summarizes the “ST” LED functions

Normal Operation

Slow Flash Green

Overload

(120%-160% Full Load)

Steady Red

I2T

(Drive Timed Out)

Quick Flash Red

Short Circut

Slow Flash Red

Under Voltage

Quick Flash Red/Yellow

Overvoltage

Slow Flash Red/Yellow

Stop

Steady Yellow

MAINTENANCE

The TurboJet requires a minimum amount of maintenance, normally limited to cleaning or replacing filters as they become filled with dirt and debris. Cleaning the 1st and 2nd stage filters daily will extend the life of the 3rd stage HEPA canister filter.

The TurboJet requires a minimum amount of maintenance, normally limited to cleaning or replacing filters as they become filled with dirt and debris. Cleaning the 1st and 2nd stage filters daily will extend the life of the 3rd stage HEPA canister filter.

Unlatch the top section and tip it back on its hinge so the debris falls into the bag from the upper section of the TurboJet and its first stage filter. Follow all local regulations on disposing of material removed from the ducts. In critical areas, such as hospitals, it is required to cover the inlet with 6-mil plastic when the job is completed to prevent the collected debris from escaping and contaminating the area while it is removed from the building to be emptied in a non- critical area where the trash bag can be disposed of safely. The first stage filter can be put into the same trash bag for disposal.

NOTE: Never wash the Pleated or HEPA filter with water.

When necessary, wash the 2nd stage filters with a garden hose and nozzle at full force. First rinse in the opposite direction of the airflow, then rinse both sides. Occasionally, a degreaser such as Air-Care Zap electrostatic filter cleaner may be required to restore this filter to its’ peak performance. Let the filter air dry before reinstalling into the unit.

Note: When there is not sufficient time to allow filters to dry before using the TurboJet, simply dry vacuum the loose debris off of the filters’ surfaces or use compressed air in an appropriate outdoor area.

When the control panel pressure gauge reads 4 1/4” or more and the 1st and 2nd stage filters are clean, the 3rd stage HEPA filter should be replaced (approximately once or

twice per year, if other filters are cleaned regularly). There is no safe way to clean the HEPA filter without a risk of damaging it.

HEPA Replacement

1. Open the upper section of the TurboJet to gain access to the filters. The first and second stage filters will be held in the upper section of the TurboMax.

2. Use care when removing the 3rd stage HEPA filter mounted in the bottom half of the cabinet. When the airflow through the inlet is noticeably reduced and the 1st & 2nd stage filters are clean, it is time to replace the 3rd stage HEPA filter.

NOTE: Applying compressed air pressure or using a vacuum brush on filter surface will damage the filter. If you have any questions regarding the HEPA filter maintenance, please call Air-Care at 800-322-9919.

PARTS AND ACCESSORIES

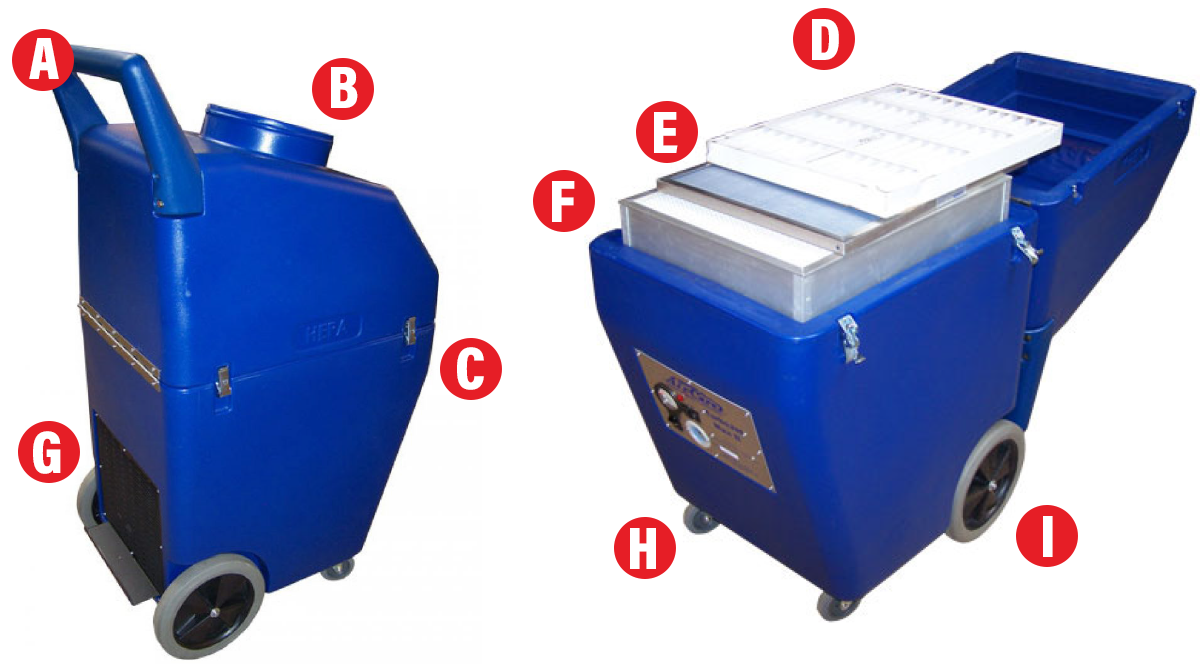

A) Molded Handle

B) 12” Dia. Hose Inlet

C) Locking Latches

D) 1st Stage 18” x 24” x 2” Disposable Pleated Filter

E) 2nd Stage 19” x 25” x 1” 82% Electrostatic Air Filter

F) 3rd Stage 18” x 24” x 6” HEPA Filter

G) Exhaust Grills

H) Front Swivel Casters

I ) 12” Non-Marking Wheels

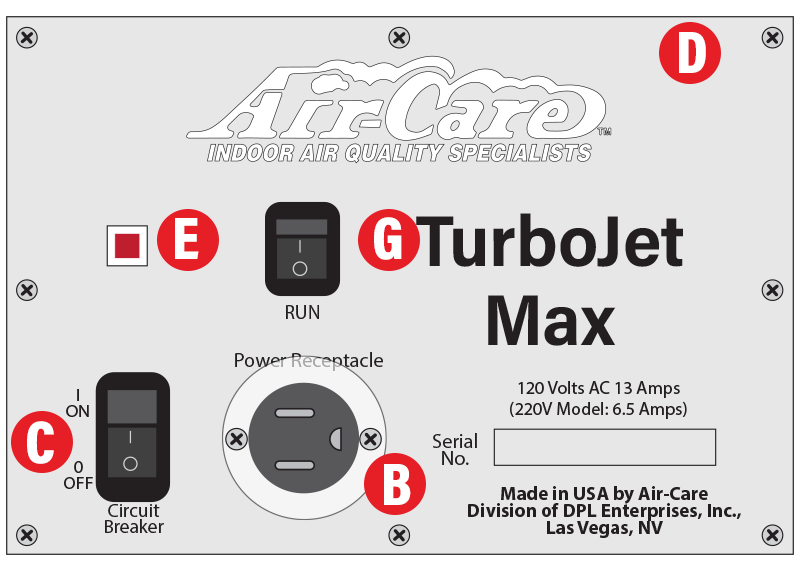

A ) Gauge, W.C. Max II ONLY

B ) Power Receptacle

C ) Circuit Breaker/Power Switch, Dual 20 amp.

D ) Max II Complete Panel & Max Panel

E ) Light, Panel “PWR” and “ST”

F ) Switch, Hi/Low Speed Max II ONLY

G ) Switch, DPST Start

LIMITED WARRANTY

TURBOJET MODELS

Turbojet Max – TurboJet Max II

Air-Care warrants this product to be free from defects in materials and workmanship to the original purchaser for a period of Three (3) years from the date of purchase. Components listed below are excluded from this Three year period and are covered for periods described below:

Blower Motors : 1 Year

Power Inverter: 1 Year

Wheels & Filters: No Warranty

Warranty covers both parts and labor (labor is to be performed at Air-Care’s facility located at 3868 E. Post Road; Las Vegas, Nevada).

Warranty is extended to the original purchaser and is not transferrable.

This warranty does not extend to any damage to a product caused by or attributable to freight damage, abuse, misuse, improper or abnormal usage. Warranty is also void if the product has been modified or altered in any way.

The purchaser is responsible for the cost of shipping the equipment to Air-Care’s facility for evaluation. If found to be defective and covered by the terms of this warranty, Air-Care will pay FedEx ground shipping charges on the repaired or replaced item back to the purchaser’s location. Any additional expedited service charges for quicker shipping shall be born by the purchaser. If the product or component is not found to be a warranty issue, the purchaser will be responsible for return shipping charges.

Air-Care is not responsible or liable for indirect, special, or consequential damages arising out of or in connection with the use of performance of the product; damages with respect to any economic loss, loss of property, loss of revenues or profits, loss of use, or other incidental or consequential damages of whatsoever nature.

The warranty extended hereunder is in lieu of any and all other warranties, and any implied warranties of any type.

This warranty gives you specific rights. These rights and others vary from state to state.

Division of D.P.L. Enterprises Inc.

3868 East Post Road, Las Vegas, Nevada 89120, (702) 454-5515, FAX (702) 454-5225

Website: www.air-care.com • E-mail: Info@Air-Care.com