UNPACKING INSTRUCTIONS

Remove the outer box and inspect for damage. Report all damage immediately to your carrier. If special set-up instructions are required, they will be taped to the outside of the equipment or in the “Operating” section of this manual.

Inspect all the packing material for small parts before discarding packaging material. Report all damage to your Carrier immediately then notify Air-Care. Any attempt at repairing suspected damages may void warranty.

PARTS CHECKLIST

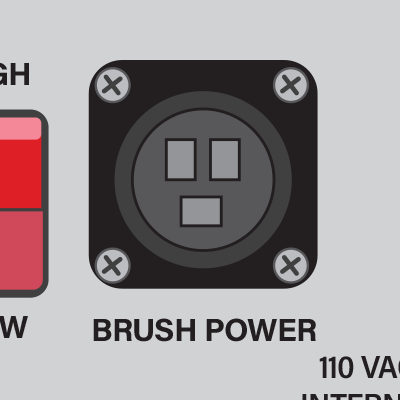

Air-Care TruckMaster II with High and Low power switch for Brush Motor

Hose, 1 ½” X 35’ Brush and Motor Assembly. Includes 12” Firm Pancake-Style Brush

Universal, Wireless Remote Control (Including 2 x AAA Batteries)

Dust Damper

Hose Coil and Carry Strap with Handle

SAFETY PRECAUTIONS

Always think safety and use common sense precautions when working with Air-Care equipment. Do not block walkways with equipment and remove delicate and breakable articles from the immediate work area. The following are precautions that should be reviewed by all persons who will be involved in the cleaning activity.

• Inspect AC power plugs to be sure the ground pins are in place.

• NEVER connect power to Air-Care equipment unless all covers and safety shields are in place. Mechanical and electrical parts could activate without warning and cause injury.

• NEVER allow anyone but a properly trained technician to use the equipment for cleaning products.

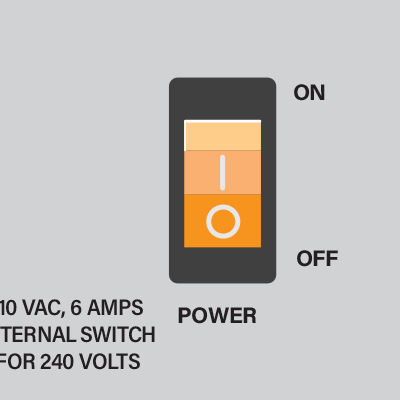

• All Air-Care equipment is designed for US standard 115-volt, 60 Hz AC. The Air-Care TruckMaster II is optionally available in 220/240 Volt, 50/60 Hz Power. Always check the specifications on the equipment before connecting electrical power to Air-Care Equipment.

If you have questions about the safe use of any Air-Care product, call 702-454-5515.

SET-UP AND TESTING

The Air-Care TruckMaster II provides a 2 Speed Duct Cleaning Motor and Brush and a 1.5” x 35 ft Vacuum Hose with 2” hose cuff and 12” Disposable “Pancake” brush, (Optional 2”x35 ft Hose and 18” brush). Vacuum is supplied by connecting the hose to a Truck Mounted Carpet vacuum machine.

Since Ducts contain dry debris and Carpet Vacuums usually require the debris to be wet to protect the Blower wheel and reduce dust, it is advised that the Dust Damper be connected between the Carpet Vacuum Hose and the TruckMaster Hose. It will also have a solution hose connector to provide just plain water at the lowest pressure and flow rate to the Dust Damper, usually 100 to 200 psi.

A. Turn off the Power switch on the panel and plug the power cord into a suitable 120-volt outlet.

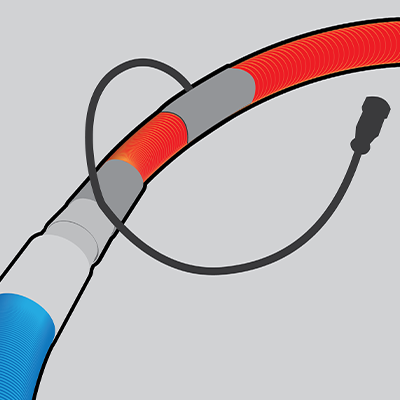

B. Attach the Brush power cable from the Vacuum hose to the round connector on the control panel. KEEP THE BRUSH AWAY FROM ANYTHING BREAKABLE or ANYTHING WITH A POWER CORD OR ROPES OR TUBES before powering it on.

The Rotating brush can quickly wrap up any loose material and it does “WALK” across the floor rapidly when turned on. BE CAREFUL, it is normally operated inside of an Air Duct.

The optional 220/240 Volt Air-Care TruckMaster II operates in the exact same way as the 120-volt version.

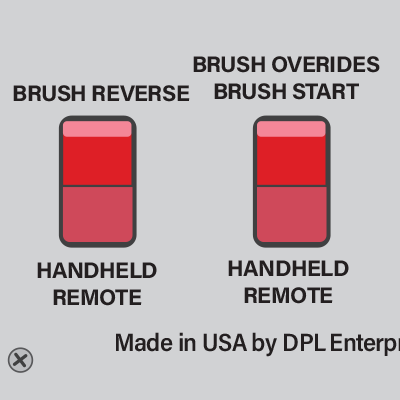

C. Brush “RUN / STOP” switch

D. Brush “CHANGE ROTATION” Switch

E. “HI /LOW” switch to control the speed and Torque of the Brush.

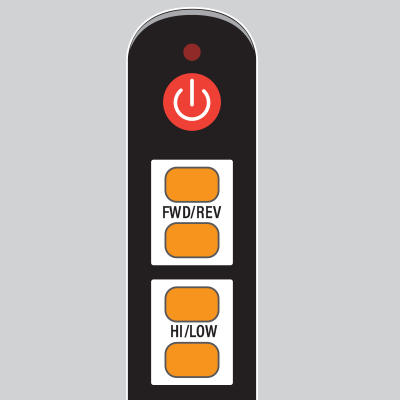

F. There is also an IR, Wireless Universal remote That can Start/Stop and Change Directions of the Brush Rotation. The remote is like a Television Remote, you must be in line of sight of the TruckMaster for it to work. It can “SEE” the remote signal while you are on a ladder or across the room, but NOT if you are out of sight or in another room.

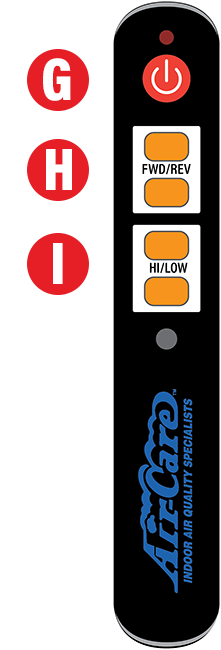

G. The TOP RED is for Start/Stop.

H. The buttons Marked FWD / REV will Change the direction of the Brush Rotation when pressed while the Motor is Running.

I. The other buttons are reserved for any new features that may be added in the future.

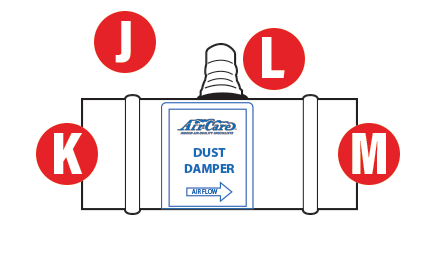

J. The dust damper protects the Truck Mount Vacuum by injecting water from the solution hose into the vacuum hose going to the truck. Set the solution pressure at the low end of the adjustment.

K. Truck Mount Vacuum Hose Connection

L. Truck Mount Solution Hose Connection

M. Connection to TruckMaster Vacuum Hose

DUCT CLEANING PROCEDURES

The Air-Care TruckMaster II has a unique dual function. The motorized brush on the end of the vacuum hose assembly agitates the dust and debris into the air duct, while your Truck Mount Vacuum functions as the debris collector. This method of cleaning only requires that the supply and return grills be removed and the air system is turned off. Caution: some air systems may automatically cycle in the OFF position on the Thermostat, so it is best to also shut off the main power breaker to the furnace while cleaning.

1. Before applying power, be sure that all 3 Switches on the Control Box are in the OFF (0) position.

2. After connecting the Air-Care TruckMaster to an extension cord and a wall outlet, turn on the Circuit Breaker on the Right, then the Motor can be started after a few seconds.

3. Connect the 1 ½” X 35’ hose assembly (or the optional 2” X 35’ hose assembly) to your Vacuum Source Hose

4. The electrical cord from the hose will plug in to the TruckMaster control panel socket. Unless your truck vacuum has provision for “Dry Dust”, you should install the “Dust Damper” between the Truck vacuum hose and the TruckMaster Hose and attach the solution hose to the truck’s solution hose.

This wets the dust so it will not damage the vacuum blower wheel. A low-pressure setting can be used for the Solution hose since it is only needed to “Dampen” the dust to prevent wear of the Truck Mount Vacuum Blower Wheel.

5. The Remote uses an Infrared Light beam like a Television Remote. The Remote Receivers are located on the control panel and on the back of the Power Box. The operator can be across the room or up on a ladder and the remote will often function with the IR beam reflecting off light-colored walls and ceilings even with obstructions to visibility.

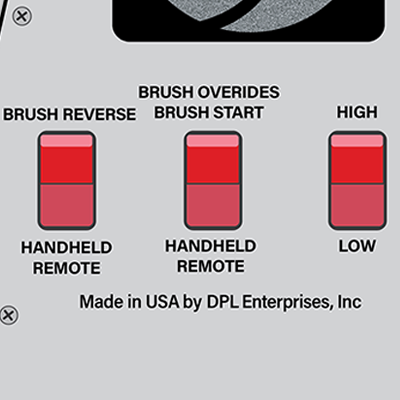

6. When using the Remote, BOTH Switches on the control box for the brush MUST BE OFF (DOWN)!

These switches can be used to manually START/STOP or Change rotation direction of the brush if the Handheld Remote Transmitter is lost or has a dead battery. When these switches are ON (UP), it deactivates the Remote.

• Once the technician inserts the brush into the duct, use the Remote’s ON/OFF Button to start the brush and gently work the vacuum hose and brush into the duct. STOP the brush before removing it from the duct.

• When the technician cannot push the vacuum hose in any farther, press the FWD/REV button on the remote to Change the brush rotation to allow it to go deeper into the ducts. Repeat this process for each supply and return duct. After a Duct Run is clean, pull the hose partially out of the duct with the motor running, but stop it before removing the brush from the duct opening.

• Where you have long ducts, such as main trunk lines without access doors, you must make “cut-ins”, to access the entire length of the duct. The cut-in must be covered with a metal plate and screwed in place with sheet metal screws, then taped with Aluminum tape.

• After cleaning each duct, each opening should then be decontaminated by fogging with our EPA registered Envirocon sanitizer, Soot Set sealer and Liquid Odor Kill deodorizer. Air Care has Single and dual tank foggers that provide a fine mist, or fog, that works well for this process.

• Other than keeping the exterior Clean, cleaning the Cooling Fan intake Filter or replacing weak batteries in the TruckMaster Remote, there are no user serviceable components in Air-Care TruckMaster II. Only trained technicians should attempt to make internal repairs on this equipment.

• Replacing a Worn Brush is a simple process that uses just one setscrew to hold the hub to the End of the Motor shaft.

• There is a replacement motor kit available for technicians that feel comfortable with simple electrical repair, but you can always call for a Repair Machine Authorization (RMA)code if you want Air-Care to Quote the cost of replacing a motor or other damaged component.

TROUBLESHOOTING GUIDE

PROBLEM 1: Remote does not operate brush.

CHECK: Be sure Handheld Remote is pointed at the Remote Receiver sensor on the top of the case.

Actions: Locate the TruckMaster II so the remote has an unobstructed view of the sensors.

CHECK: Check that the Red indicator on the Handheld remote flashes (Once) when The RED Power Button or when the either of the FWD/REV Buttons are pushed. The Other buttons may not flash, that is normal.

Actions: If the red LED does not flash, replace the battery in the remote.

CHECK: Is Power Cord Plugged in to a good power outlet?

Actions: The remote module is powered by Power plug it into a known good outlet.

PROBLEM 2: Brush & hose cannot be inserted far enough into duct.

CHECK: Duct is too small for hose (Less than 2” wide opening).

Actions: Be sure you are using the 1 ½” X 35’ Hose, Brush and Motor Assembly.

CHECK: Duct makes two 90 degree turns in less than 12 inches.

Actions: Try to access the duct from another opening.

PROBLEM 3 : Brush motor does not turn.

CHECK: Electronic Torque control shut down brush motor power.

Actions: Stop Motor then restart it to reset the unit.

CHECK: There was a power loss in the building or a power surge.

Actions: Be sure the Brush Switch on the Panel is OFF. Try using the handheld remote again.

CHECK: Motor Connectors have come loose.

Actions: Be sure Brush Power Cable is fully inserted into the Connector on the front of the TruckMaster II.

CHECK: NEW High Lift Brush used in older unit without 2-Speed Motor or New machine set to LOW.

Actions: Use Brush with thinner bristles or Be sure that the Motor Panel Switch is on HI.

PROBLEM 4: There are holes in the red vacuum hose.

CHECK: The “crush proof” hose is very durable, but if it is pulled excessively hard, it can separate at the grooves.

Actions: Call Air-Care for an RMA to get a quote to have the cable housing repaired or replaced, 800-322-9919 or 702-454-5515 info@air-care.com.

BRUSH MOTOR REPLACEMENT KIT

This new version of the Brush Motor and Mount retains all the advantages of the original and includes some improvements to reliability, durability, and Debris Collection. It has more POWER so the New DuctMasters have a 2 position Switch for HI and Low.

This new version of the Brush Motor and Mount retains all the advantages of the original and includes some improvements to reliability, durability, and Debris Collection. It has more POWER so the New DuctMasters have a 2 position Switch for HI and Low.

Installing a new motor in a DuctMaster without the Hi/Lo switch could run the FIRM brush fast enough to cause damage to older ducts. If in Doubt about the Ducts condition, use the SOFT 12” Brush with the smaller, .021” Bristles. Contact Air Care for questions about using the Newer Motor on existing DuctMasters or TruckMasters. 702-454-5515.

The Hoses, Motor and electrical Connections for the new version will fit previous DuctMaster Models.

KEEP THE NEW MOTOR FULLY ASSEMBLED!

First remove the OLD motor and mount from your hose:

1. Remove the screws holding the Motor Mount collar on the end of the hose and save the screws and nuts to mount the new motor and mount. One screw also secures the internal stiffener to the interior of the hose. (Some stiffeners are Steel, and some are Fiberglass)

2. Cut the 3 wires for the motor leaving enough cord to crimp (or solder) the wires to the new motor wires. All 3 wires will need to be the same length for this new Motor Connection.

3. You will no longer need any of the parts in the original motor assembly unless you are returning it to Air-Care with an RMA for warranty evaluation.

Installing the NEW Motor Assembly.

1. Be sure you have all the parts for the installation:

- Your original Screws, 10-32 x 5/8” long machine screws,

- 10-32 Hex Nuts with built in Lock Washers.

- Metal or Fiberglass Stiffener (if it was on the original hose)

2. Remove the outer insulation from the black power cord in the hose to expose the 3 insulated motor wires about 2 inches long.

3. Strip the insulation from all 3 wires about ½” back from the ends.

4. Slide the larger black Shrink Tubing over the cable. It will slide over the new connections after the wires are connected.

5. Slide the 3 pieces of smaller shrink tubing over each of the motor wires. The connections can be made by Crimping the new connectors or soldering them. If you are planning to solder the connections, be sure the blue shrink tubing is far enough away from the heated ends to prevent it from shrinking prematurely from the heat of soldering.

6. The wires may be different colors from the Motor than the ones from the hose cable. The order is not important, the brush will operate with any combination of wires, but it may turn in the opposite direction in some cases but will still change directions as before.

7. Each of the 3 wires from the hose can now be inserted into the Crimp connectors on the new motor. Try to twist the wires tight enough so that all the strands go into the silver connector, then crimp it with a crimping tool. Alternately, the wires can be soldered, if so, be sure they are heated to a point where the solder flows into all the strands and into the silver connector. The Motor is a low voltage, HIGH AMP device and a poor connection will result in faulty performance.

8. Slide the Blue shrink tubing over the metal connector; Heat the tubing to shrink it in place. A hair dryer, heat gun or even a cigarette lighter can be used. Be careful to not burn yourself, the plastic hose or heat the other shrink tubing at this time.

9. Connect the other 2 wires following the same procedure.

10. When all 3 wires are connected and insulated, slide the larger black shrink tubing over them and as far towards the motor as possible. Heat this shrink tubing to shrink it on to the wires.

11. Next, slip the Nylon Loop Strap over the wires. This will guide the wires. The Loop Strap will be held in place with one of the 10-32 x 5/8” screws used to hold the black nozzle on the hose.

12. Insert the screws into the mounting holes in the Nozzle and thread the screws into the original holes in the hose if possible. If this is difficult, you may need to drill new holes in the hose using the 2 holes in the Black Nozzle as a guide. Use a 3/16” diameter drill.

13. When the screws are in place, place the loop strap hole over one of the screws and install one of the nuts then tighten the screw with a screwdriver. It may be necessary to use a screwdriver to thread the screws through the loop strap.

14. If your hose has a stiffener, install its loop over the other screw, install the nut and tighten it. If there is no stiffener, just install the nut and tighten the screws.

15. Your repair and upgrade are now complete and ready to test. If you have any questions, please call Air-Care Tech Support, 800-322-9919.

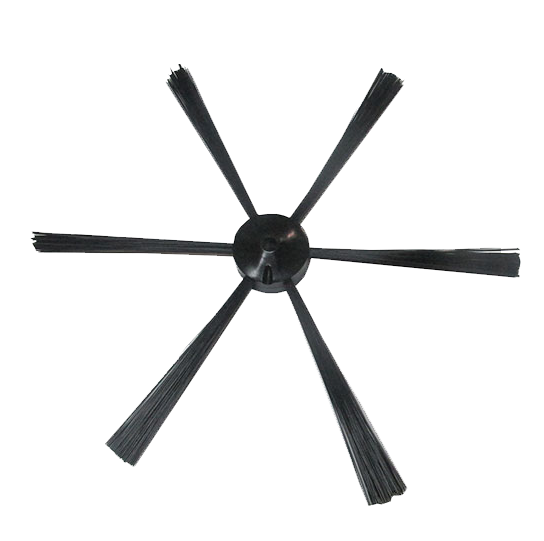

PANCAKE-STYLE BRUSH

12″ Brush

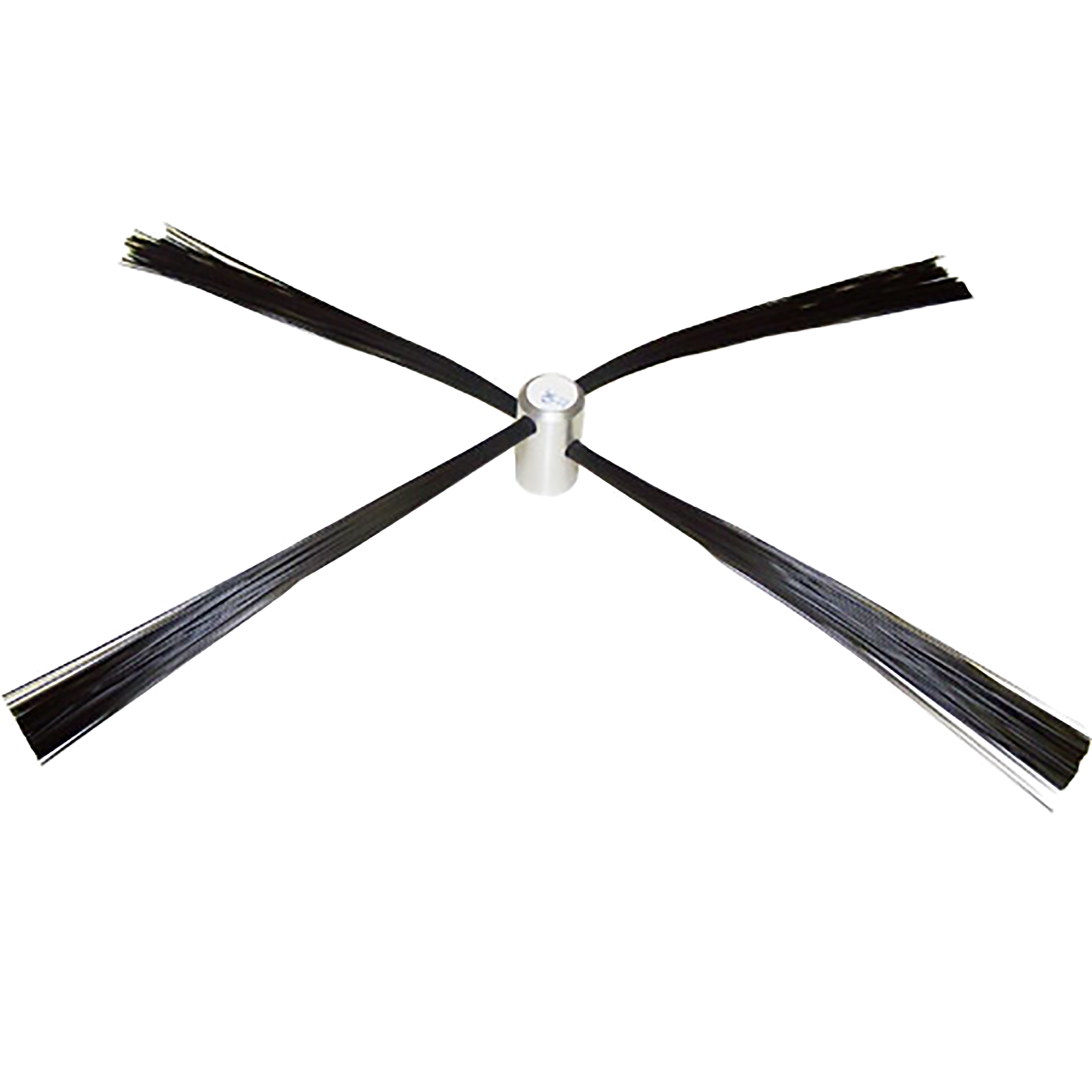

18″ Brush

With the addition of the higher power Brush Motor with HI and LOW Switch (On Panel Only), the Standard Brush is the Firmer 12” Pancake Brush .045” dia.

Bristles, which is disposable and can be purchased singly or in a 5 Pack. It can be used in the LOW Speed mode for Internally insulated and older Flex ducts, but always inspect the duct for brittleness or flaking insulation before cleaning. If your machine only has a single speed, these ducts should only be cleaned with the softer 12” brush (.021″ Dia. Bristle) Disposable

Pancake Brush. The “Pancake-Style” hubs allow either brush to negotiate sharp turns in smaller air ducts and are even more nimble with the slightly shorter new motor.

The New, Firm version of the brush floats higher in the duct, especially on the “HI” setting of the Panel Switch.

It will function in older ducts with the “LO” Setting just as the original 12″ .021″ Bristle version does.

The 2”, BLUE Vacuum Hose and motor now have an 18” brush with .045” dia Bristles in the traditional Disposable

Pancake Hub. The stiffer bristles raise the brush higher in the duct, especially when the Panel Switch is in “HI” setting. The Aluminum hub 18” Brush with .032” dia. Bristles is now optional.

The 12” Brushes will work on the 2” (Blue) hose.

While the New 18” Brush will fit on the 1.5” hose, there are some situations where the 18” brush may not start properly with the Original Single Speed Motor.

LIMITED WARRANTY

TRUCKMASTER II

Air-Care warrants this product to be free from defects in materials and workmanship to the original purchaser for a period of Three (3) years from the date of purchase. Components listed below are excluded from this Three-year period and are covered for periods described below:

Circuit Board & Remote: 1 Year

Power Supply: 1 year

Hose & Motor Assembly: 90 Days

Brushes: No Warranty

Warranty covers both parts and labor (labor is to be performed at Air-Care’s facility located at 3868 E. Post Road; Las Vegas, Nevada).

Warranty is extended to the original purchaser and is not transferable.

This warranty does not extend to any damage to a product caused by or attributable to freight damage, abuse, misuse, improper or abnormal usage. Warranty is also void if the product has been modified or altered in any way.

The purchaser is responsible for the cost of shipping the equipment to Air-Care’s facility for evaluation. If found to be defective and covered by the terms of this warranty, Air-Care will pay FedEx ground shipping charges on the repaired or replaced item back to the purchaser’s location. Any additional expedited service charges for quicker shipping shall be borne by the purchaser. If the product or component is not found to be a warranty issue, the purchaser will be responsible for return shipping charges.

Air-Care is not responsible or liable for indirect, special, or consequential damages arising out of or in connection with the use of performance of the product; damages with respect to any economic loss, loss of property, loss of revenues or profits, loss of use, or other incidental or consequential damages of whatsoever nature.

The warranty extended hereunder is in lieu of any and all other warranties, and any implied warranties of any type.

This warranty gives you specific rights. These rights and others vary from state to state.

Division of D.P.L. Enterprises Inc.

3868 East Post Road, Las Vegas, Nevada 89120, (702) 454-5515, FAX (702) 454-5225

Website: www.air-care.com • E-mail: Info@Air-Care.com